Real time delivery shown at checkout

Browse Products

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

What is plastic extrusion?

The word ‘extrusion’ implies a pushing out action. In terms of plastic extrusion this is the process of heating raw materials and pushing the molten plastic compound through a tool raw plastic to the desired shape. Water is then used in a cooling process to ensure the plastic extrusion retains the correct shape. We have many different tools with many different shapes that can be used to manufacture a large range of extruded plastic profiles. There are many different types of plastic profile including plastic trim which is often used for edging purposes. In cases where tooling is required to be made, this is called bespoke or custom plastic extrusion.

What type of plastic extrusions do you stock?

As well as manufacturing plastic extrusions, we also supply them direct to our customers. We offer a large range of extruded plastic profiles on our online shop. Our top three extruded plastic profiles are:

Note that plastic angle trims also go by the name of plastic angle, PVC angle or PVC corner trim and a black plastic trim is also available. We also offer many other shapes, including:

Plastic trims explained

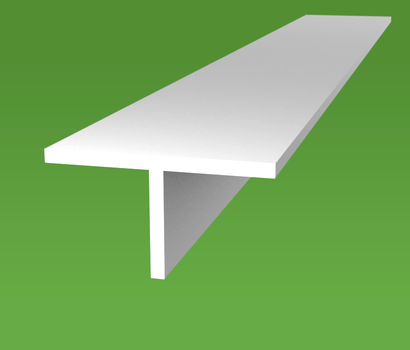

The phrase ‘plastic trims’ is a popular term for types of extruded plastic profiles which are used to trim edges and corners. Using plastic trims can provide a neat and professional finish to raw or unsightly edges which need to be protected or hidden. Depending on the application, there are different types of plastic trims that could be considered. These are three popular examples:

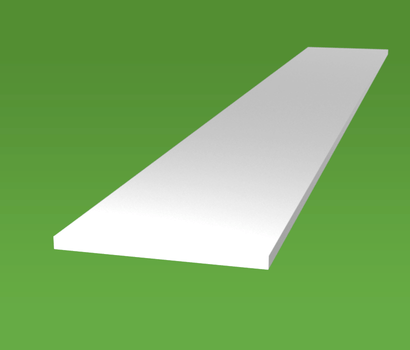

Flat plastic trim

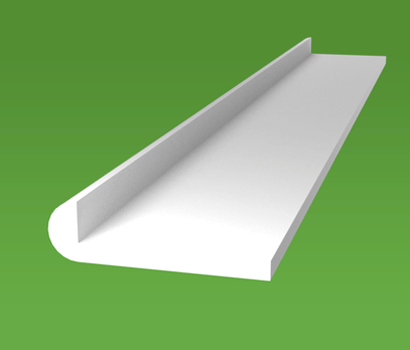

Flat Plastic Trim – often used to trim and protect edges, flat plastic trim is sometimes called PVC cover strip

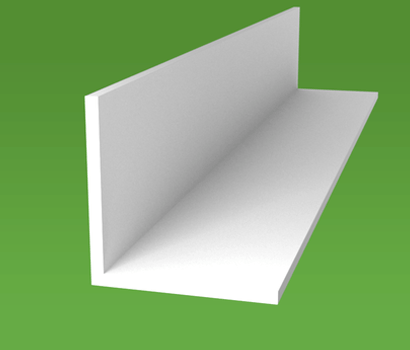

L shaped plastic trim

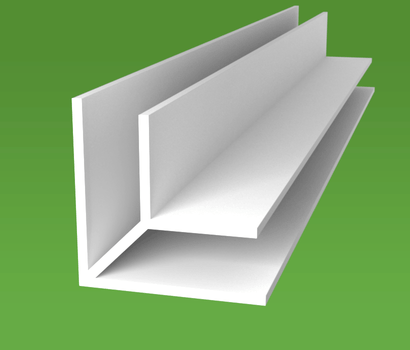

L Shaped Plastic Trim – often used to protect and trim corners, L shaped plastic trim is a ninety-degree right angle with straight edges

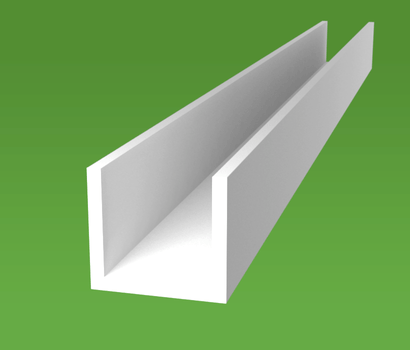

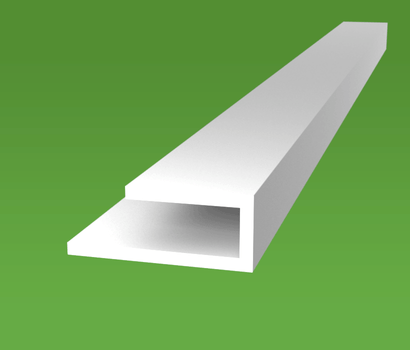

Plastic U channel

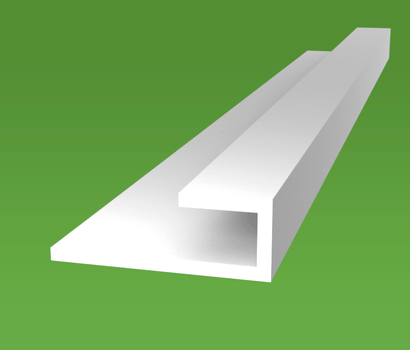

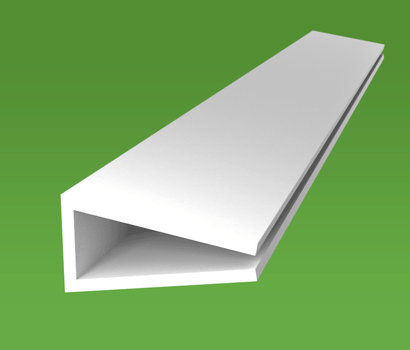

Plastic U Channel – often used as an edging trim for boards and panels, plastic U channels have three straight sides for using on solid edges

There are several other types of plastic trim profiles available in our stock range. The type you choose will depend on your particular application.

Plastic extrusions from stock

We manufacture plastic extrusions 24 hours a day during the week and keep a lot of stock to keep delivery times to a minimum.

How long does delivery take?

If an order is placed on our online shop before 4pm, and the products are in stock, the extruded plastic profiles will be despatched as a next day delivery to mainland Great Britain. If the goods are out of stock we would manufacture the plastic profiles and they should be with you in three clear working days.

Samples of plastic extrusion

We are happy to send out short pre-cut samples of plastic extrusions so you can check the shape, colour and dimensions. These are sent by Royal Mail and are free of charge.

What is an extruder?

An extruder is a device that creates extrusions by pushing or pulling a material through a shaped die to form a continuous length with a pre-set cross section. Extruders can be used to create a wide variety of products by shaping various materials.

How does an extruder machine work?

Raw material is fed from the hopper into the barrel of the extruder machine where it is heated and consequently melted. Screws in the barrel force the material through a die which gives the shape to the end product which is then cooled.

Plastic extrusion company in the UK

Our factory is located in Cornwall in the UK, and we are able to deliver to mainland Great Britain.

What are plastic extrusion profiles?

In terms of plastic extrusion the word ‘profiles’ is often used. The definition of ‘profile’ is ‘an outline of something as seen from one side, often referring to a face but it can be applied to other things. Profiles in the extrusion manufacturing industry refer to the shape of the plastic extrusion products. So plastic extrusions are the same as plastic profiles.

The material that we use for our plastic trims

Our stock profiles are manufactured from PVC, and this is often called uPVC. But what does uPVC actually mean? The term PVC is short for ‘polyvinyl chloride’ and ‘u’ is short for ‘unplasticised.’ So uPVC means that the plastic material used for our plastic trims is unplasticised polyvinyl chloride.

The rigid plastic profiles in our stock range are manufactured from uPVC. But it is important to note the difference between the plastic material we use and the plastic material used in the double-glazing and window industries. Additional stabilisers are often added to standard uPVC in those industries, which are not used for our uPVC profiles.

Our uPVC trim is often used as edge protection for boards and panels as well as for many other applications. If you are looking for uPVC trim we have a huge range, all available in 75 metre packs.

What are plastic extrusions used for?

Plastic extrusions are used for many types of application, but these are a few of the most popular uses:

Corner protection

Plastic angle trim and corner joints are popular plastic extrusion profiles for this type of usage. Using corner protection can not only protect edges and corners of various surfaces, but also covers rough or sharp edges.

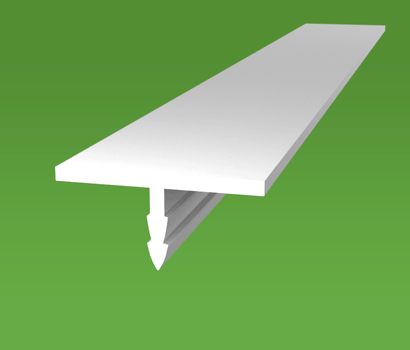

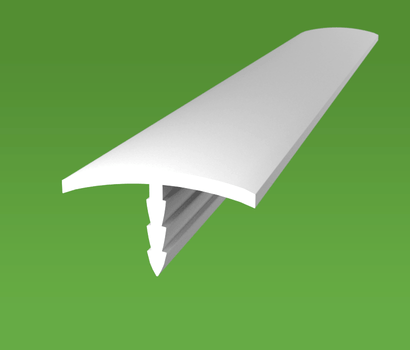

Edging trim

Plastic angle trim, channels, flat strips, J channels, lipping, T barbs and capping are extrusion profiles that are often used as edging trim. If you want to hide edges that may be a raw, uneven or damaged these types of plastic extrusion may offer a solution.

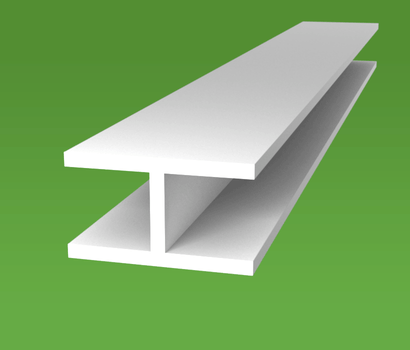

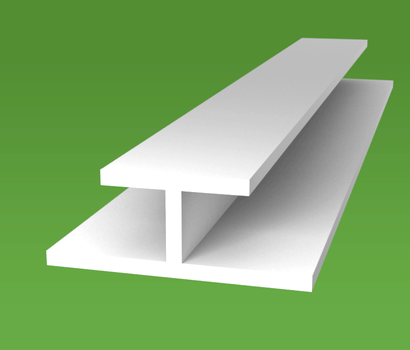

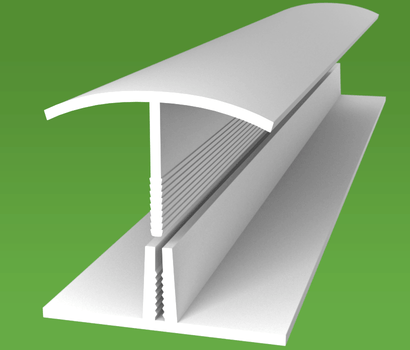

Joining boards and panels

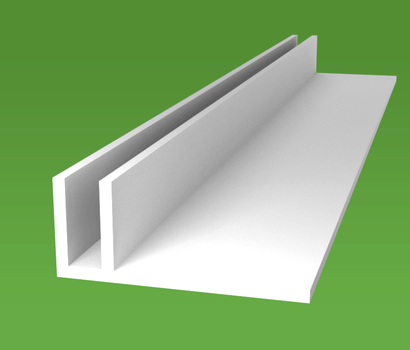

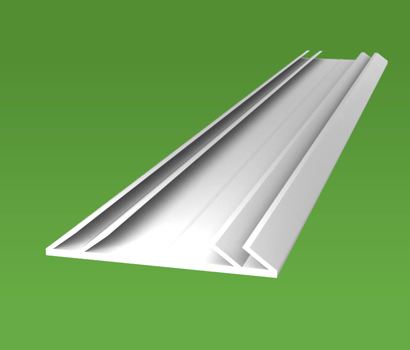

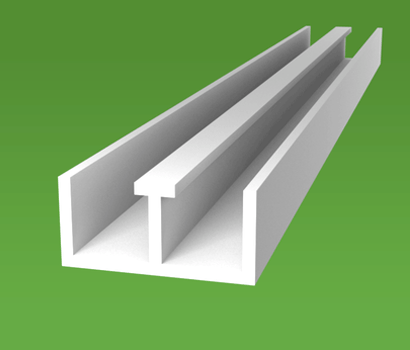

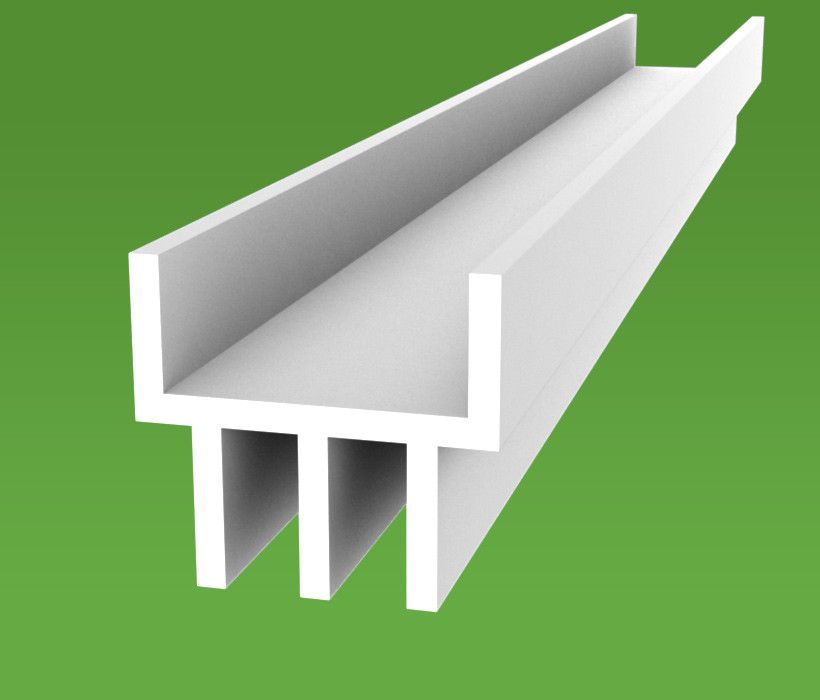

H section (equal, unequal & interlocking) are three types of extruded plastic profile that can be used for joining boards, panels and partitions. The equal profile has two wings of equal size, and the unequal profile has one wings that is longer than the other. The interlocking H plastic profile is a two-part system where the top and base plastic profiles clip together.

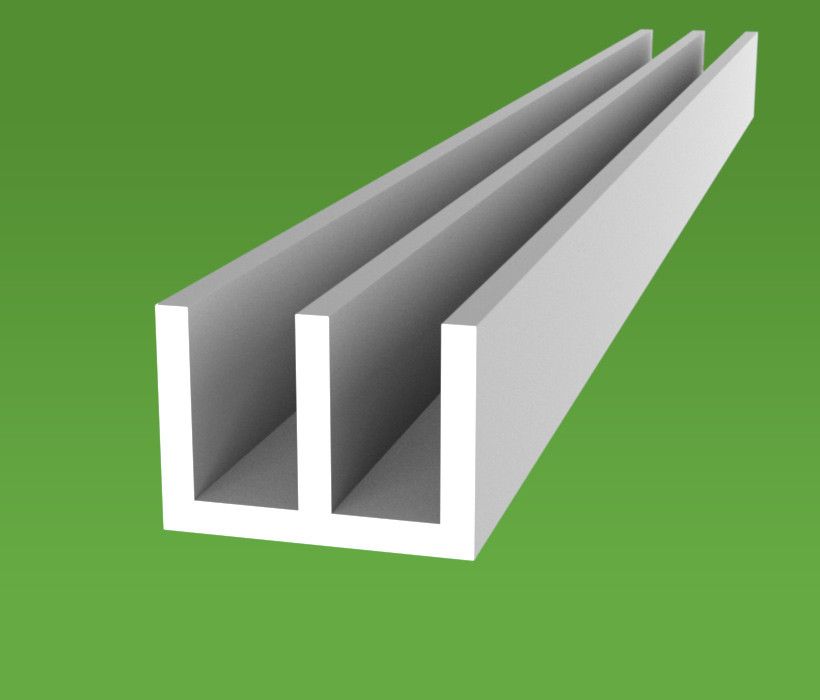

Sliding track

U channels, double channels and vivarium channels are types of plastic profiles that are often used as sliding track. The U channel contains a single channel for inserting board or glass. Double channels include two channels for this purpose. Vivarium channels also will clip onto the board or cabinet as well as holding two pieces of glass.

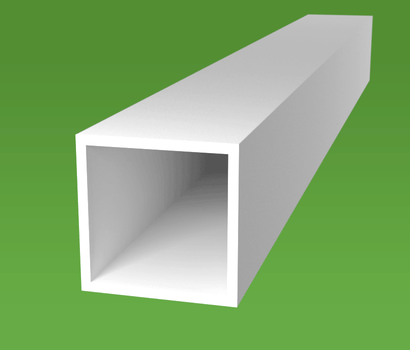

Spacers and gap fillers

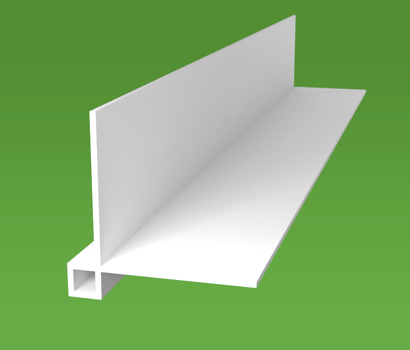

Square tubes, flat strips, T sections and F sections are plastic extrusions which in some situations can be used as spacers and gap fillers.

Accreditations for the manufacture of plastic extrusions

We have been accredited with two British Standards for many years. Each year we are externally audited for both Quality and Environmental systems. Using these two standards we follow a Quality & Environmental Management System (QEMS). We follow many internal systems whilst manufacturing plastic extrusions which ensures a consistent approach and ultimately leads to customer satisfaction.

Quality standard

BS ISO 9001:2015 is a standard that specifies requirements for a quality management system (QMS). Organisations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

Environmental standard

BS ISO 14001:2015 is a standard that specifies the requirements for an environmental management system (EMS) that an organisation can use to enhance its environmental performance.

Categories